This experience focuses on the process of fractional distillation, a sophisticated method designed to separate or purify components from complex liquid mixtures, such as fog rinse, by leveraging the differences in boiling points of its constituents. The objective is to isolate and analyze the diverse volatile components present in the fog rinse, observing temperature variations to pinpoint the boiling of various elements at specific temperatures

Educational Goals

- Deep dive into fractional distillation: Gain a comprehensive understanding of fractional distillation’s principles and its application in separating complex liquid mixtures based on boiling point disparities.

- Precision in temperature control: Emphasize the significance of precise temperature control for the selective vaporization of mixture components, highlighting the crucial role of temperature in the distillation process.

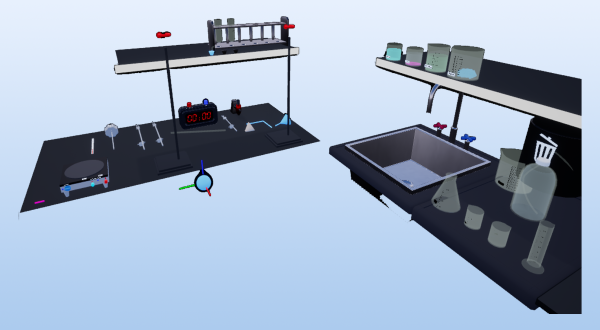

- Proficiency with laboratory equipment: Acquire skills in using essential laboratory apparatus, such as Erlenmeyer flasks, heating plates, and condensation setups, crucial for executing fractional distillation.

- Insights into chemical properties: Enhance knowledge about the physical properties of mixture components, particularly boiling points, and understand how these properties can be utilized for effective separation.

- Application of theoretical concepts: Foster the ability to apply theoretical knowledge in a practical setting, enriching understanding of chemical separation and purification techniques.

This laboratory experience in fractional distillation serves as a practical exploration into the separation and purification of complex mixtures. By focusing on the distillation of fog rinse, participants learn not only about the operational aspects of fractional distillation but also about the importance of precise temperature control and the correct use of laboratory equipment. The activity aims to provide a hands-on understanding of how different boiling points can be exploited to separate a mixture into its constituent parts, thereby offering a real-world application of theoretical chemical concepts. Through this process, participants gain valuable insights into the physical properties of substances and the practical methodologies for their separation, enhancing their skills and knowledge in chemical analysis.

Protocol

- Using the 70mL graduated cylinder; measure approximately 70 mL of 25% ethanol solution.

- Pour the measured liquid into the 250 mL Erlenmeyer flask.

- Insert the magnetic stir bar into the Erlenmeyer flask.

- Close the Erlenmeyer flask with the two-hole stopper including the glass elbow.

- Insert the thermometer into the hole of the stopper with a glass elbow. The thermometer must be immersed in the mouthwash; but should not touch the bottom of the Erlenmeyer flask.

Warning! The glass elbow can break if it is not inserted in line with the hole.

- Place the Erlenmeyer flask on the hot plate.

- Fill the 600 mL beaker two-thirds full with ice and cold tap water.

- Place the beaker to the right of the hot plate.

- Attach a universal clamp to the support; at a height of approximately 20cm (bottom position).

- Attach test tube 1 to the clamp.

- Attach the other clamp to the support; at a height of approximately 30cm (top position).

- Attach the purple connector to the top clamp.

- Start the magnetic stirrer.

- Start the stopwatch.

- Adjust the temperature of the heating plate to 85°C.

You can monitor the results in the Temperature vs. Time tab in the results table.

- When the liquid no longer rises in test tube 1 (after approximately 2 minutes following reaching 85°C):

– detach the purple connector from the test tube and monitor the condensation.

– remove the universal clamp from the top.

– detach test tube 1 and place it on the test tube rack.

- Attach test tube 2 to the bottom clamp.

- Reattach the other clip to the holder; at a height of approximately 30cm (top position).

- Attach the purple connector to the top clamp.

- Adjust the temperature of the heating plate to 105°C.

- Monitor the appearance of another temperature plateau in the results table.

- When the solution has completely evaporated from the Erlenmeyer flask:

– detach the purple connector from the test tube and monitor the condensation.

– remove the universal clamp from the top.

– detach test tube 2 and place it on the test tube rack.

- Turn off the stirrer and reduce the target temperature of the hot plate to 15°C.

Anticipated Outcomes

This laboratory exercise demonstrates the process of distilling a 25% v/v ethanol solution, focusing on the separation of ethanol from water based on their different boiling points. The procedure involves heating the solution, vaporizing the ethanol, and then condensing it back into a liquid form in a separate container.

The expected outcomes are:

- Heating the ethanol solution: By adjusting the heating plate to 85°C, the ethanol, with a boiling point lower than water, begins to evaporate. This step is crucial for separating ethanol from the solution.

- Ethanol evaporation and condensation: As ethanol vaporizes, it travels through the setup and condenses upon cooling, collecting in a separate test tube as a distillate. This demonstrates the principle of distillation, where a substance is separated based on its boiling point.

- Temperature plateau: The temperature plateau observed indicates the phase where ethanol is being evaporated. Since ethanol has a lower boiling point than water (78.37°C at standard atmospheric pressure), it evaporates first. The subsequent rise in temperature indicates the beginning of water evaporation.

- Separation and collection of ethanol: The ethanol, now separated from the mixture, is collected in a test tube. This process showcases how distillation can be used to separate and collect components of a mixture based on their physical properties, specifically boiling points.

- Complete evaporation: Increasing the temperature to 105°C ensures the removal of water, demonstrating the complete evaporation of the solution’s components at different temperatures.

The significance of this experiment lies in illustrating the practical application of distillation, a fundamental technique in chemistry for separating and purifying liquids. It provides insight into how different substances in a mixture can be separated based on their boiling points. This technique is widely used in various industries, including pharmaceuticals, beverage production, and chemical manufacturing. Understanding this process is crucial for students and professionals in the field, as it highlights the importance of boiling points, phase changes, and the principles of distillation in both laboratory and industrial settings

Summary of Assignment by Grade Range

Grades 3-5 (Ages 8-10)

- Focus: Basic introduction to distillation and simple observations.

- Activities: Observing phase changes, simple demonstration of distillation, basic safety instructions.

Grades 6-8 (Ages 11-13)

- Focus: Intermediate understanding and application of distillation techniques.

- Activities: Performing basic distillation, using lab equipment, observing temperature effects, following detailed safety protocols.

Grades 9-12 (Ages 14-18)

Activities: Conducting detailed distillation, using advanced lab equipment, adjusting experimental parameters, performing detailed analyses, adhering to advanced safety protocols.

Focus: Advanced mastery of distillation and in-depth analysis.

Laboratory essentials

Instruments

- Beaker (50ml & 1000ml)

- Erlenmeyer (250 ml)

- Funnel & Funnel filter

- Glass Rod

- Graduated Cylinders (70ml)

- Hot plate

- Lab Stand & Clamps

- Magnetic stirrer

- Plastic connector

- Test tubes. Thermometers & Timer

Products

- 25% v/v ethanol (solution)